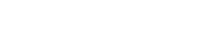

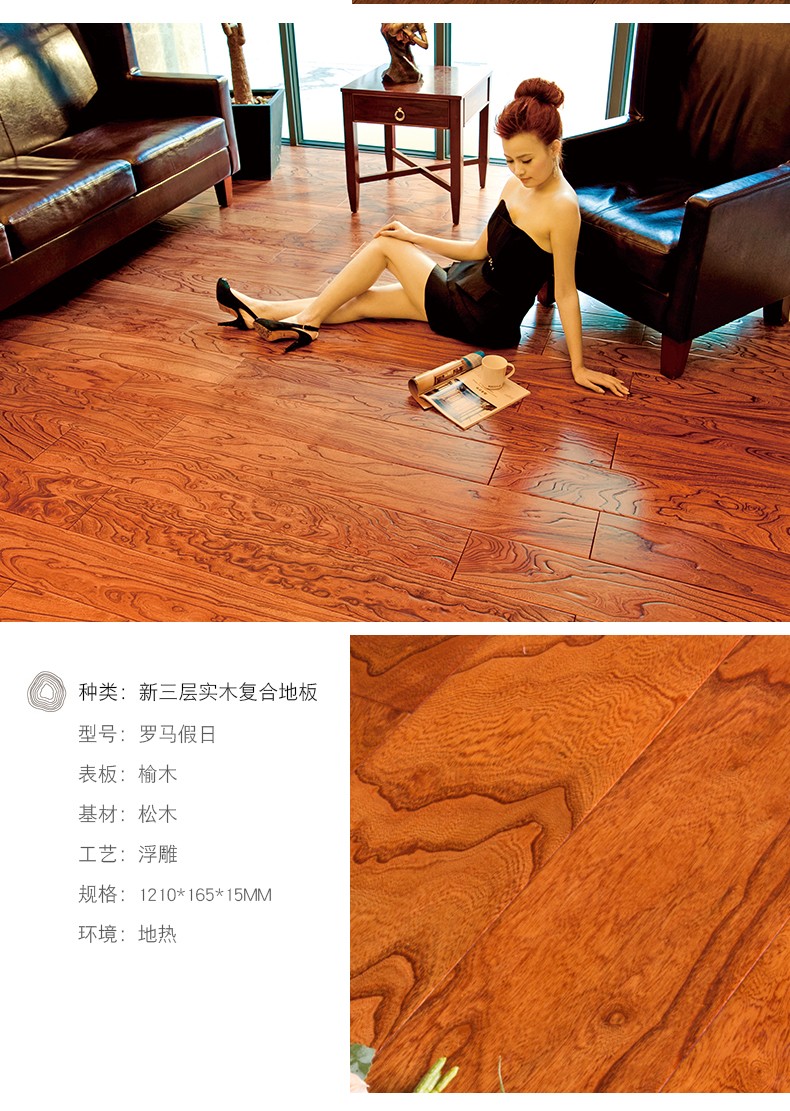

Lianyi New three ply engineered floor

Traditional solid wood composite floor is divided into solid wood three layers and solid wood multilayer (7, 9, 11) two, solid wood composite floor has the natural texture texture and elasticity of real wood floor, and overcome the common problem of natural solid wood floor easy to expand and shrink deformation, but also has the characteristics of agglutinate floor anti-deformation, corrosion resistance and easy to clean. Based on the above advantages, Lianyi developed a new three-layer solid composite floor. This series of floor made a huge change in the balance layer of the three-layer solid composite floor, effectively improved the stability of the product, greatly improved the inherent composite index of solid composite floor, and made the most perfect presentation of all the advantages of solid composite floor.

The difference between the new three-storey solid wood composite floor and the three-storey and multi-storey (7, 9 and 11 floors) solid wood composite floor:

1. Different layers -- The more layers, the more glue is used, and the worse the environmental performance. Say so, it is not the number of layers is more had better, and the number of layers is not equivalent to floor thickness. Buy floor board, answer with environmental protection health is first. The environmental protection level of the new three-layer structure solid wood composite floor in the solid wood composite floor has been a leading standard, environmental protection and health!

2. Different core materials -- the new three layers and three layers of core materials are made of solid wood veneer, while the seven layers and nine layers are made of ordinary wood sliced into thin slices, which are crisscross and crisscross, multi-layer combination, and then bonded by environmental protection waterproof adhesive and multi-layer thin slices through high temperature and high pressure composite. Therefore, the new three layers and three layers of core materials are better quality and more environmentally friendly! And production cost should be lower than real wood floor, adhere to the cost-effective route.

中 | ENGLISH

中 | ENGLISH Bidding system

Bidding system Recruitment

Recruitment